Key takeaways:

- Manufacturers need to design maintenance-free devices which are reliable for optimum asset monitoring in worst-case scenarios.

- The best way for manufacturers to develop safe devices is to follow ATEX, IECEx and HazLoc rules and standards.

- Nexxiot follows all three certification paths in its supply chain solutions. But what do the various label parameters actually mean?

When it comes to fleet management, smart device manufacturers and users want devices that do not require any manual handling after installation. To achieve this, manufacturers need to design a maintenance-free device, which doesn’t need battery exchange and is reliable in worst-case scenarios.

In the railway and marine industry, a worst-case scenario means dangerous goods are being loaded, transported and unloaded. Some of these goods may include explosive gases and liquids, but also combustible flyings and conductive dust. So what can a manufacturer do to ensure their clients never have to remove devices when dangerous goods are being transported? The best way is to follow ATEX, IECEx and HazLoc rules and standards when developing safe devices for optimum supply chain solutions and event reporting.

ATEX refers to directives of the European Union, which set requirements for workplaces and equipment used in explosive atmospheres. IECEx is an international certification scheme from the International Electrotechnical Commission, and targets all countries around the world. Hazloc certification is based on the commonly used explosion protection standards for North America.

Nexxiot follows all three certification paths. This is how we ensure highly reliable devices that meet our stringent safety standards. The labeling indicates the different certifications, but what do the various label parameters actually mean? Read on to find out.

ATEX

The “Ex” in the hexagon is the ATEX mark. “II” stands for the group of equipment. Group II refers to equipment intended for use in other places than underground parts of mines liable to be endangered by explosive atmospheres. “2” stands for the equipment category. There are three equipment categories: 1, 2 and 3. Category 2 must be designed and constructed:

- To prevent ignition sources arising, even in the event of frequently occurring disturbances or operating faults, which always need to be taken into account.

- So that their stated surface temperatures are not exceeded, even when risks arise in abnormal situations anticipated by the manufacturer.

“G” stands for explosive atmospheres caused by gases, vapors or mists. “D” stands for explosive atmospheres caused by dust. Equipment with both “G” and “D” can be used in explosive atmospheres caused by gases, vapors or mists, and explosive atmospheres caused by dust.

IECEx

“Ex” indicates that the equipment corresponds to one or more of the types of protection that are subject to specific IEC 60079 standards. “ib” indicates two things: type and level of protection. In this case, “i” means the device is intrinsically safe. Intrinsic safety is a type of protection where the electrical circuits themselves are incapable of causing an explosion in surrounding explosive atmospheres.

Level of protection “b” stands for a high level of protection. There are also “a” and “c” levels of protection, with “a” as the highest level. Protection level “a” is typically used for equipment constantly exposed to explosive atmospheres. Since this is not the case with Nexxiot devices, protection level “b” is sufficient.

Protection “ib” takes into account one countable fault and is not capable of causing ignition in such circumstances. In other words, devices designed to have protection “ib” have double safety measures; if one fails, the other is there to guarantee safety.

“IIC” is the equipment group. Equipment of group “II” is intended for use in areas with an explosive gas atmosphere other than mines. The “C” is a subdivision and stands for gases like hydrogen and acetylene. There are also subdivisions “A” and “B”. Devices designed for subdivision “C” cover subdivisions “A” and “B”.

“T4” is the temperature class for group “II” equipment, i.e. for equipment used in explosive gas atmospheres. “T4” means the maximum surface temperature of a device will never exceed 135°C. There are 6 temperature classes, the highest being “T6” or 85°C. Since the majority of gases have ignition temperatures above 135°C, class “T4” is enough to guarantee sufficient safety.

The level of protection “Gb” is similar to “ib” and stands for equipment for explosive gas atmospheres, with a “high” level of protection.

“IIIC” is the equipment group. Equipment of group “III” is intended for use in areas with an explosive dust atmosphere other than mines. The “C” is a subdivision and stands for conductive dust. There are also subdivisions “A” and “B”. Devices designed for subdivision “C” cover subdivisions “A” and “B”.

“T135°C” is the maximum surface temperature for group “III” equipment, i.e. for equipment used in explosive dust atmospheres. “T135°C” means the maximum surface temperature of a device will not exceed 135°C. The level of protection “Db” is similar to “ib” and stands for equipment for explosive dust atmospheres, having a “high” level of protection. “-40°C ≤ Ta ≤ + 60°C” shows the ambient temperature range in which the device is designed to be used.

How do ATEX and IECEx correlate?

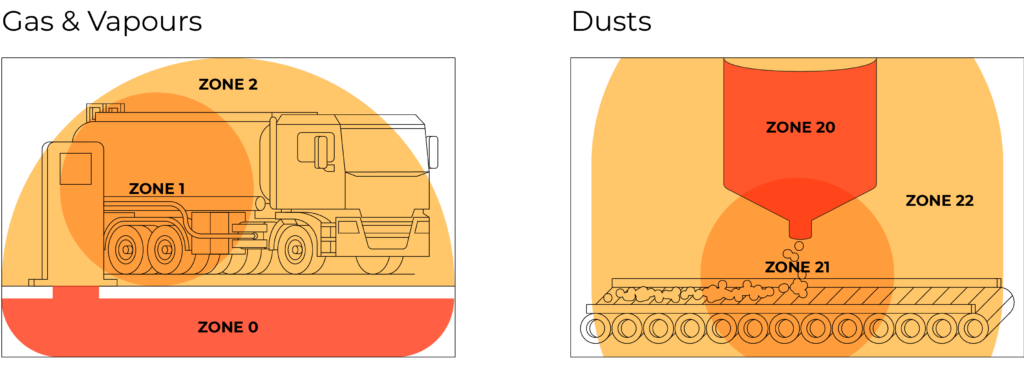

The “2 GD” of ATEX correlates to IECEx “Zone 1” and “Zone 21”, which require protection levels “Gb” and “Db”. “Zone 1” and “Zone 21” are areas in which an explosive gas and/or dust atmosphere is likely to occasionally occur during normal operation.

You can see the differences between the various zones here:

Figure 1 IECEx zones.

In general, Nexxiot devices are safe to use in the transportation of dangerous goods. Devices with these markings should never be installed in places where an explosive atmosphere is continuously or frequently present for long periods, such as the inside of gas tanks.

Hazloc:

The Hazloc marking can be made up of two parts: one based on zone and the other on class and division location classification. The marking shown above includes both ways of marking.

Hazloc marking requires the logo of the NRTL which assessed and certified the device. In this case, you can see the MET Mark from Eurofins E&E (formerly MET Laboratories) has been used. The “c” in the logo stands for Canadian approval and the “US” for American approval. So this means the device has been assessed according to American and Canadian standards.

The first two lines are similar to the IECEx marking, so we only need to take a look at the differences.

“Class I” locations are those in which flammable gases, flammable liquid–produced vapors, or combustible liquid–produced vapors are (or could be) present in the air in quantities sufficient to produce explosive or ignitable mixtures.

“AEx”, similar to “Ex”, stands for equipment built to American standards. Equipment built to Canadian standards would have “Ex”.

The third line shows the class and division location classification.

“Class I” is explained above.

“Class II” locations are hazardous as a result of the presence of combustible dust.

“Class III” locations are hazardous because of the presence of easily ignitable fibers, or where materials producing combustible flyings are handled, manufactured, or used, but where those fibers/flyings are unlikely to be in the air in quantities sufficient to produce ignitible mixtures.

“Class I, Division 2” location is one where there is an explosive atmosphere of gases or vapors mixed with air when an abnormal condition exists, such as failure of a containment wall or ventilation system.

“Class II, Division 2” is a location where incendive concentrations of inflammable gases, vapors, or liquids do not usually occur under normal operating conditions.

“Class III, Division 2” is a location in which flammable fibers are stored or transported.

“Groups A, B, C and D” are potentially explosive gases and vapors. Typical gases and vapors for the groups are:

– Group A: Acetylene

– Group B: Hydrogen

– Group C: Ethylene

– Group D: Propane

“Groups F and G” are combustible dusts.

“Group F” atmospheres contain combustible carbonaceous dust. Coal, carbon black, charcoal, and coke dust are examples of carbonaceous dust. “Group G” atmospheres contain combustible dust not included in Group E or F. These include flour, grain, wood, plastic and chemicals. “T4” means the maximum surface temperature of a device will not exceed 135°C or 275°F.

How do zone and class/division location classifications correlate?

Unfortunately, there is no one-to-one correlation. Equipment designed for Zones 1 and 21 can be used in Division 2 areas. On the other hand, equipment designed for Division 1 can be used in Zones 0, 20, 1 and 21. When Nexxiot devices are installed correctly on assets with enough distance to the point of vapor release, they are safe to use in areas with either zone or class/division location classification.

Literature/Sources

- DIRECTIVE 2014/34/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014

- IEC 60079-0, Ed.7.0

- IEC 60079-11, Ed. 6.0

- National Electrical Code, 2020